Cayeli, Turkey — Now that areas affected by last year’s cave-in have been fully rehabilitated and repaired, the Cayeli underground copper-zinc mine in Turkey is experiencing high production rates.

The mine, which is operated by Cayeli Bakir Isletmeleri (CBI), a Turkish company owned 55% by

For the first nine months of 2003, Cayeli recovered 23,300 tonnes copper and 24,700 tonnes zinc in concentrates from the milling of 666,000 tonnes of ore grading 4.1% copper and 5.2% zinc at a cash cost of US44 per lb. copper and a total cost of US50 per lb, net of zinc and byproduct credits. Recoveries averaged 85% for copper and 71% for zinc.

“This indicates we have put the events of the October twenty-fifth [2002] ground fall behind us,” says Jochen Tilk, Inmet’s chief operating officer.

Cayeli is in the Black Sea region of northeastern Turkey, 8 km inland from the coastal town of the same name and 100 km west of the Georgian border. During a recent visit to the site, The Northern Miner learned the Turkish government intends to privatize its 45% minority interest in Cayeli by way of a public tender process over the course of the next 12 months.

“We will carefully monitor the developments of the government’s initiative,” says Tilk. “Inmet is an interested party and intends to participate in the tender process when it takes place.”

In October 2002, Cayeli experienced a series of underground rock falls in the main access ramp, triggered by the sudden failure of an ore pillar in the mostly mined-out upper south area of the mine workings. There were no injuries or damage to equipment, but production was suspended for a month and a half to allow for rehabilitation of the affected areas. The mine’s hoisting shaft in the footwall side of the ore body was unaffected. Mining resumed in December 2002 from the lower levels of the orebody, initially at a 50% reduced production rate. Most of Cayeli’s production now originates below the 900-metre level, which was not affected by the ground fall. The rock fall has had no material impact on reserves.

“Over the past months, Cayeli has implemented measures, with a marginal impact on operating costs, to minimize the probability of a similar event,” says Tilk. As a consequence of the ground fall event, CBI has taken steps to move its future infrastructure into the footwall of the orebody and change its mining sequence of stopes to improve the ground conditions around the mine workings. The existing infrastructure was developed in the hangingwall, and production has come from three main blocks to date: the 820-880 level, 900-960 level and 980-1,060 level. The development of the 760-800 level will start in 2004.

Previously, CBI used sub-level retreat/longhole stoping methods to mine from the edges of the orebody inwards to the centre. It is now mining from the central pillar outwards. The maximum stope length is 25 metres, with a width of 6-7 metres. In addition, a seismic monitoring system has been installed. During the sill development of stopes, every single round is supported by cable bolting and shotcreting.

Understandably, Cayeli did not meet its 2002 production goal, but it did achieve a mill throughput of 895,000 tonnes at an average grade of 4.2% copper and 5.1% zinc — the most on a daily basis since operations began in 1994. Daily mill throughput improved to 2,896 tonnes in 2002, against 2,815 tonnes in 2001. Production totalled 32,600 tonnes copper and 33,100 tonnes zinc for 2002 at a cash cost of US43 per lb. copper and a total cost of US48 per lb., compared with 33,000 tonnes copper and 25,300 tonnes zinc in 2001 from the milling of 816,000 tonnes averaging 4.6% copper and 4.5% zinc. Cash costs were US47 per lb. copper, with a total cost of US51 per lb. Mill recoveries averaged 87% for copper and 72% for zinc in 2002, versus 88% and 69% in 2001.

Cayeli generated $16 million in free cash flow for 2002. The mine is expected to repay its existing debt in full by mid-2004, with scheduled debt repayments of $7 million in 2003 and $3 million in 2004.

“Cayeli has established sufficient stopes, and its flexibility to mine from various areas has improved greatly,” says Tilk. For the full year, the mine should meet its zinc production target of 36,000 tonnes. However, copper grades were hampered by limited stope availability in the first part of the year, and original estimates of 39,000 tonnes have been adjusted downward to 35,000 tonnes.

Proven and probable diluted reserves at the end of 2002 were estimated at almost 16 million tonnes grading 3.6% copper and 5.7% zinc, plus 0.5 gram gold and 47 grams silver per tonne, based on a cutoff grade of 2.5% copper-equivalent, which corresponds to a copper price of US90 per lb. These reserves are equivalent to 571,000 tonnes copper, 903,000 tonnes zinc, 260,000 oz. gold and 23.9 million oz. silver.

At current production capacity rates, Cayeli has 12 years of reserves remaining. In addition, there are 3.3 million tonnes of inferred resources grading 5.8% copper and 8.7% zinc. Over the past several years, the mine has converted all of its resources to reserves. In the past three years, about 7 million tonnes in proven and probable reserves have been added as a result of definition drilling in the deep part of the orebody.

Approximately 40% of existing reserves lie below the bottom of the hoisting shaft, which extends 285 metres down to the 830 level. CBI intends to deepen the shaft by 295 metres to the 540 level in order to provide access to the lower part of the orebody, which will become the source of production over the coming years. A new ore-handling system will be installed at the 570 level, in addition to the loading facility at the 900 level. A key feature of the existing shaft is its double-hoisting system, which will allow Cayeli to continue hoisting ore while driving the extension at the same time. “Our ability to produce at the rates we’re forecasting and sink the shaft is a technical challenge,” notes Tilk.

The shaft-deepening is being contracted out, and should get under way in 2005. Inmet says the project will cost US$14 million and last 28 months.

Joint venture

CBI was formed in 1983 as a joint venture between Phelps Dodge, with a 49% stake, Etibank (now Eti Holdings), with 45%, and Gama Endustri, a private Turkish company, with 6%. Richard Ross, president of Inmet, says Inmet’s predecessor, Metall Mining, paid somewhere between $10 million and $20 million in 1988 to purchase Phelps’ stake. In early 2002, Inmet increased its equity interest in CBI by acquiring Gama’s 6% interest for $13 million.

Construction of the Cayeli underground mining operation and on-site concentrator plant began in November 1992 at a capital cost of US$150 million. The first concentrate shipment was made in December 1994. Cayeli began mining and milling operations at an original design rate of 1,350 tonnes per day, or 650,000 tonnes per year. The first couple of years were rocky ones for Cayeli, as the mine experienced significantly poorer operating and financial results than were suggested by the feasibility study. The mineralogy of the orebody was found to be more complex than originally thought, resulting in lower metallurgical recoveries and inferior quality concentrates. In 1996, Inmet wrote down its investment in Cayeli to the tune of $132 million.

Cayeli began to turn around in 1997, when it achieved record throughput of 762,000 tonnes. This — combined with improved copper grades and recoveries, and higher realized copper and zinc prices — resulted in strong operating earnings and cash flow.

Mine development reached a stage where production stopes were fully available for mining. In order to process the increased ore, operators converted the original rod mill to a primary ball mill. Various ore types were campaigned separately to eliminate zinc contamination in copper concentrates, which had previously been caused by blending of high-grade clastic ores. Additional flotation cells were added to the mill in both the copper and zinc circuits in an effort to increase recoveries and improve concentrate grade and quality.

A 5.5-metre concrete shaft and ore-handling system were commissioned in May 1998. The hoisting shaft system replaced the trucking of ore up the decline, resulting in lower costs. Mill throughput improved 10% to 2,300 tonnes per day in 1998.

Tailings pipeline

CBI has continued to fine-tune and expand both the mine and mill facility to where it is now expected to reach an annualized rate of 3,425 tonnes per day, or 1.25 million tonnes per year, by the end of 2003. The joint venture has incurred about US$50 million in additional capital expenses since the mine was built in 1994, including US$8 million in 2002 relating to the replacement of a new long-term and higher-capacity tailings pipeline, and a 25% expansion in mill throughput capacity. Mill improvements included the installation of a tertiary crusher and new concentrate filtering capacity to handle the clastic ore, which has proven metallurgically challenging. The last upgrade to the mill was done in April 2003, with the installation of new column cells to improve zinc recoveries. Capital expenditures in 2003 are expected to reach US$11 million.

“We believe we have good capacity,” says Tilk. “We’ve upgraded our fleet, we have a lot of new equipment now, and we have developed new stopes.”

From 1994 to the end of 2002, the mine produced 6.2 million tonnes grading 4.5% copper and 6% zinc.

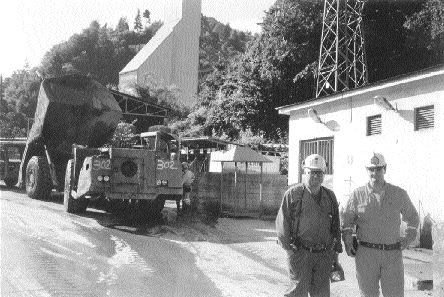

The plant is on the western flood plain of the Buyukdere River, directly across from the village of Madenli.

Run-of-mine ore is stored in eight 3,500-tonne surface stockpiles and delivered by trucks to the crushing plant, where it is stored in separate bins, based on ore type. These bins act as a buffer between the mine and mill, and allow blending of ore types, which is key to the mill performance. Mill feed is prepared by blending, according to ore types and grades. The blending recipe is based on a front-end-loader bucket count.

From there, the ore is dumped into a feed hopper, where, after screening, it goes through a 3-stage crushing process to minus 15 mm. The tertiary crusher was added to facilitate processing of the clastic ore, which was proving to be the bottleneck in Inmet’s goal of achieving 1.25 million tonnes per year. A single-stage grinding circuit utilizes two ball mills, with 70% of the final flotation feed passing 36 micron.

The copper flotation circuit consists of a 3-stage cleaning and re-grind facility. Copper rough scavenger tailings feed goes to the zinc circuit. Concentrates are pressure-filtered to an 8-9% moisture content. About 60% of the mill tailings are mixed with cement and pumped underground as backfill in the mined-out stopes. The remainder is transported 7 km by pipeline along the Buyukdere River Valley for deep-water discharge into the Black Sea. A second pipeline is used to dispose of waste water. The pipeline extends 3.4 km into the Black Sea and discharges tailings at a depth of 250 metres. Cayeli is only one of seven mines in the world that use a submarine tailings disposal system.

Cayeli produces both a copper and zinc concentrate to spec from the blending of the black and yellow ores. The processing of the clastic ore yields a clean zinc concentrate, as well as a copper concentrate that is zinc-rich but off-spec. The quality of the clastic copper concentrate is said to be improving as the zinc level declines.

The concentrates are trucked 28 km to a port facility at Rize, on the coast of the Black Sea. Roughly 70% of Cayeli’s copper and zinc concentrates are sold under long-term contracts, with the balance sold in the spot market at prevailing market prices.

The right to use the Rize port facilities is subject of various litigation proceedings among CBI, the Turkish Department of Transportation, and the private operators of the port. A revised lease for the Rize port has been under negotiation since mid-1999. CBI has made arrangements with another port facility at Hopa to ship its concentrates from there should the Department of Transportation deliver a notice ordering CBI to vacate the Rize port within seven days. The government agency has deferred serving any eviction notice in light of continuing discussions to settle the dispute.

In May 2003, a 3-year collective bargaining agreement with Cayeli’s hourly workforce expired, and negotiations regarding a new agreement are expected to commence in the fourth quarter. Mine production was halted previously, by a 2-month-long strike in 1998 and a 3-month strike in early 2000. The mine’s workforce totals 379, including 256 hourly workers and 123 staff members, with only five expats.

Geology

Cayeli is a late Jurassic-age, Kuroko-type volcanogenic massive sulphide (VMS) deposit extending over a strike length of 800 metres and to a vertical depth of at least 600 metres. In thickness, it varies from a few metres up to 100 metres, for an average of about 20 metres. It dips 55-70 to the northwest and remains open at depth and in some directions on the sides. “It’s not completely closed off by drilling, the way it stands,” says Chief Geologist Robert Sim, who points out that a scissor fault cuts the deposit, displacing the Main and Deep Ore zones. “In terms of size and grade, this has got to be one of the better VMS deposits in the world, especially for a Kuroko deposit.”

The deposit comes to surface and has been known for thousands of years, with activity dating back to Roman times. In the early 1900s, there was some limited Russian activity, indicated by the presence of a small adit just up from the head frame. The exploration arm of the Turkish state agency MTA drilled and evaluated the area from the mid-1960s to the mid-1970s.

Phelps Dodge got involved in the mid-1980s, driving an exploration decline and performing drilling, bulk-sampling, and pilot-plant tests. Inmet took over in 1988.

The deposit occurs in the eastern Black Sea Pontide volcanic belt at the contact between altered footwall felsic rhyolitic flows and pyroclastics, and hangingwall mafic tuffs and basalts. The massive sulphide mineralization consists of pyrite, chalcopyrite and sphalerite, with lesser amounts of galena and tetrahedrite. Metallurgically, the Cayeli orebody is complex. The ore is divided into three categories and mined selectively: yellow ore, which is copper-poor; zinc-rich black ore; and the metallurgically challenging clastic ore, which is zinc-rich with a fragmental texture. At the mill, the clastic ore is treated either in batches or at specific lower rates. The sphalerite in the clastic ore is typically fine-grained, with intergrowths and inclusions of copper. The yellow and black ores are blended together in the mill.

Underneath the massive sulphide deposit is extensive stringer-zone mineralization of pyrite and chalcopyrite, some of which is ore grade, though highly variable. “It surprises me that for a deposit this big, you can go from one stope that runs two or three per cent zinc, and seven metres away in the stope next door it runs ten or twelve per cent zinc,” says Sim. “It can change that quickly.”

Cayeli will continue to explore in the vicinity of the orebody in hopes of being able to expand existing reserves. “The push for exploration of this deposit has started to pick up some steam,” says Sim. “There hasn’t been a lot of exploration done on surface, outside of the deposit.” The deepening of the shaft and the future development of the lower ore zone will provide access for future exploration of the undefined boundaries of the deep orebody. Exploration drilling of the deeper holes from surface has proved challenging, owing to the rugged terrain. In addition, most of the land in the immediate area is privately owned, with lots of agricultural crops, and Sim says getting permission for access has not been easy.

CBI intends to use the experience gained at Cayeli to look for additional reserves by extending its search outward from the current resource base. “We’re beginning an integrated surface exploration program through geology, geochemistry, geophysics and drilling.” says Sim. “We’re compiling all the historic data in the area.”

In July, CBI entered into an agreement to buy the surrounding Rize property from

Cerattepe

Earlier this year, CBI reached an agreement with Teck to buy the Cerattepe deposit, near Artvin in the country’s northeastern region. The property is within 200 km of Cayeli and contains a high-grade VMS copper deposit plus a near-surface, gossanous, oxide gold-silver zone. The copper deposit hosts a drill-defined reserve and resource of 3.9 million tonnes grading 5.2% zinc, 1.2 grams gold and 25 grams silver. The tonnage of the oxide material is 8.2 million tonnes grading 3.9 grams gold and 128 grams silver. Teck completed almost 34,000 metres of core drilling on 15-metre centres and drove a 101-metre-long exploration decline.

The deal calls for an initial payment of US$2 million on closing, followed by US$4.5 million on the earlier of 18 months after closing or the start of commercial production. A third payment of US$4.5 million is due 12 months after commercial production or no later than the end of 2006.

CBI is interested only in the high-grade massive sulphide deposit, as it represents an opportunity to supplement production from Cayeli with additional low-cost copper production of roughly 20,000 tonnes per year. Prefeasibility work by CBI indicates a single, discrete, coherent high-grade copper zone in the massive sulphides containing a probable reserve of 1.3 million tonnes grading 10% copper, 0.5% zinc, 1.3 grams gold and 29 grams silver. CBI intends to study the feasibility of developing the high-grade zone based on a 250,000-tonne-per-year underground operation using a combination of cut-and-fill and longhole stoping methods. The zone would be reached via a decline.

The project is being evaluated under the assumption that the Cerattepe material will be processed in a separate parallel plant on the Cayeli site. It is believed the high-grade secondary chalcocite copper in the Cerattepe deposit would activate the sphalerite in the Cayeli ore if the two were blended. Instead, the two lines would share only the thickeners, drying circuit and tailings facilities of the existing plant, with a blending of concentrates at the tail end.

“We’re still in the planning stages, listening closely to the concerns of the local community and discussing with various government departments what their requirements will be,” explained Oguz Karamercan, Cerattepe’s project co-ordinator. Originally, Teck planned to develop Cerattepe as an open-pit mine using cyanide to recover the gold, along with the construction of a tailings dam. “There were lots of concerns regarding that project, but our approach is completely different,” says Karamercan. “Most of those [earlier] concerns are now eliminated.”

The feasibility study, permitting, environmental work, and development are expected to be completed in 18 months.

Inmet enjoyed a third-quarter profit of $40.8 million (or $1.01 per share), including a $31.2-million gain from the sale to

Net income for the first nine months of 2003, before the gain on the sale of the NPI, was $22 million (47 per share), versus $6.7 million (10 per share) in the initial three quarters of 2002.

Operating cash flow in the third quarter was $35 million (89 per share), bringing the year-to-date figure to $52 million ($1.32 per share). The company generated significant free cash flow in the quarter, which had increased its consolidated cash balance to just under $100 million at Sept. 30 from $68 million at the end of the second quarter.

For the nine months ended Sept. 30, 2003, Inmet realized $15.1 million in operating earnings for Cayeli, compared with $16.7 million a year earlier. Operating earnings were hampered by foreign exchange rates and significantly lower production in the first quarter of 2003.

Be the first to comment on "Inmet’s Cayeli back on track"