Through its 40% ownership of the Diavik diamond mine in the Northwest Territories and a 51% interest in luxury jeweler Harry Winston,

Aber acquired its controlling interest in Harry Winston in April 2004 for US$85 million, including US$20 million in the form of working capital. The remaining interest in Harry Winston is held by Fenway Partners, a private equity firm, with 29.5%, and Ronald Winston, a member of the Winston family, with 19.2%.

Harry Winston accounted for US$156 million in sales for Aber in the fiscal year ended Jan. 31, 2005, representing a 21% increase over the comparable period a year ago. The jeweler turned a profit of US$4.5 million for the 10-month period from the date of Aber’s acquisition.

“Our acquisition of a controlling interest in Harry Winston has proven to be a complementary business for the mining side of Aber,” states Aber in its 2004 annual report. “Harry Winston, once a key player in rough diamonds, has, through Aber, re-entered this marketplace by purchasing important rough diamonds for polishing, and ultimately retail sale, in our stores throughout the world.”

Harry Winston maintains eight retail salons around the world, including New York City (where it is headquartered), Beverly Hills, Las Vegas, Paris, Geneva, Tokyo, Osaka and Taipei. The company’s collection of necklaces, bracelets, earrings, rings and wrist watches are primarily crafted and designed in-house using high-end, gem stones. Harry Winston timepieces are also sold through a network of independent distributors.

As Aber Chairman Robert Gannicott explains: “Our strength in the diamond market gets translated into improved sales and earnings [as a result of Aber’s interest in Harry Winston], and of course that benefit flows back to us as a shareholder.”

World demand for retail jewelry grew 6.8% in 2004. The U.S. dominates the retail scene, accounting for more than half of global sales. James Pounds, Aber’s senior vice-president of diamond management, notes that a healthy demand is also driven by India and China, and points to exciting growth areas in Turkey and the Middle East. The only lacklustre region this past year was Europe, he says, adding: “Decreased inventories of polished stones at cutting centres have also allowed demand to thrive and prices to increase proportionally.”

And according to Thomas O’Neill, president of Aber and CEO of Harry Winston, Japan continues to account for strong jewelry sales.

During the past year, a new management team was established under O’Neill’s leadership. As a former executive vice-president of Tiffany & Co. (tif-n) and CEO of Louis Vuitton Moet Hennessy’s jewelry division, O’Neill has a wealth of experience in the luxury goods business.

Harry Winston plans to open several new stores this year, expanding to 25 salons by 2008 and ultimately more than 40 retail outlets by 2012. Sales are projected to grow by a compound annual rate of 15-20%, well above the retail industry average of 10-13%.

“The expansion program is significant in terms of scope and investment,” says O’Neill. “The average cost of inventory for a new store is in excess of US$10 million.”

In the first quarter ended April 30, 2005, Harry Winston’s sales totalled US$41.6 million, down from a seasonal peak of US$59.3 million in the previous fourth quarter but, says O’Neill, “considerably better than our projection.” Earnings amounted to US$1 million.

Aber has an option to buy the remaining 49% of Harry Winston in slightly less than five years at a fixed formula market valuation. Should Aber choose not to exercise that right, Harry Winston can be sold as an entity, including Aber’s 51% stake.

Aber earned US$13.6 million (or 23 per share) in the first quarter of fiscal 2006, compared with US$29.5 million (51 per share) in the preceding quarter and US$2.8 million (5 per share) in the first quarter of fiscal 2005. Operations generated a cash flow of US$21.9 million in the recent quarter, versus US$37.7 million in the corresponding period of the previous year. Aber’s solid financial under-footing has allowed it to boost its quarterly dividend rate by 67% to US25 per share, starting July 15, 2005, which equates to an annual level of US$1 per share. At the end of the first quarter, Aber held US$135 million in cash and cash-equivalents.

Aber’s 40% interest in the Diavik mine accounted for US$68.5 million in diamond sales in the first quarter of fiscal 2006, versus US$85.3 million in the fourth quarter of 2005 and US$42.1 million in the first quarter of 2005. The company held three rough diamond sales in each of the past two quarters; however, the sale in this particular quarter was abnormally weighted toward smaller, cheaper stone sizes.

Harsh climate

“On a quarterly basis, this is our dullest quarter for diamond sales,” says Gannicott, adding that, in the far north, December and January are the coldest, darkest months of the winter. The Diavik mine, which accounted for 7% of the world’s diamond production by value in 2004, operates in the harsh Arctic climate. Production is influenced by weather conditions and slows down during the winter months that correspond to Aber’s first and fourth fiscal quarters. “As long as this mine relies solely on open-pit mining, there will always be this seasonal complicity,” says Gannicott.

Last year, Aber earned US$53.1 million (92 per share), largely on the back of diamond sales totalling US$253 million. Aber’s share of production in 2004 was 3 million carats of rough diamonds. Under an offtake agreement, Tiffany & Co. is committed to buying a specific assortment of at least US$50 million worth of rough stones annually for 10 years.

As the owner of a majority 60% interest, London-based

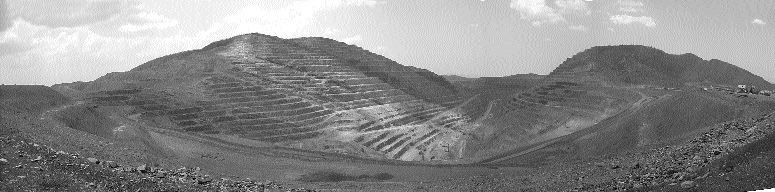

Each of the four pipes was to be mined sequentially by open-pit methods, followed by underground mining on A-154 South and A-418 in the latter part of the project’s life. A series of water-retaining dykes was eventually to be built, out from the shore, surrounding the kimberlite bodies. The first of the dykes was built around the A-154 South and North pipes, which are being mined from the same pit as they are only 100 metres apart.

The feasibility-stage mine plan was based on kimberlite reserves of 27.1 million tonnes grading 3.9 carats per tonne, or 107 million carats valued, on average, at US$62 apiece.

In 2003, the first ramp-up year of operations, Diavik produced more than 3.8 million carats of rough diamonds mined exclusively from the A-154 South pipe at an operating cash cost of US$31 per carat. As the open pit expanded in 2004, Diavik began mining and processing lower-grade ore from the A-154 North pipe.

Full capacity

The process plant easily outperformed expectations and continued to progress to full capacity ahead of the time frame originally envisioned in the feasibility study.

The Diavik mine produced 7.6 million carats in 2004 as a result of treating 1.9 million tonnes of kimberlite ore averaging 3.88 carats per tonne at a cash cost of US$23 per carat. During the year, the process plant operated at sustained rates in excess of 2 million tonne per year, well above projected feasibility levels of 1.5 million tonnes per year and the year’s target of 1.7 million tonnes. The annualized production rate during the fourth quarter was 1.8 million tonnes.

For the first three months of 2005 (on a calendar basis), Diavik recovered more than 1.7 million carats as a resu

lt of processing 493,000 tonnes of ore grading 3.55 carats per tonne. That represents a 16% increase in carat production over the fourth quarter but a 23% decrease from the third quarter of last year. Fourth-quarter production was largely affected by a greater emphasis on the processing of lower-grade ore from the A-154 North pipe. Ore processed in the current quarter was mined equally from A-154 North and the higher-grade A-154 South pipe. Cash operating costs, quarter over quarter, fell by US$7, to US$26 per carat, as more carats were recovered, owing to improved grade and increased processing rates.

In April 2003, Aber sold its first parcel of run-of-mine diamonds from the A-154 South pipe for US$96 per carat, well above the US$79-per-carat valuation used in an independent feasibility study done for Aber in 2000. Since then, neither Rio Tinto nor Aber has disclosed realized carat sale values or volumes.

“We are careful not to share diamond price information with Rio Tinto because obviously Rio Tinto has exactly the same diamond production that we have to sell each month,” explains Gannicott. “We’re careful, therefore, not to signal through public disclosure or any other way the pricing that we receive for our share of the diamonds. That would be in conflict of anti-trust legislation.”

At Aber’s annual meeting, James Pounds remarked on the robustness of the rough diamond market, particularly for larger stones at the medium- and high-quality end.

“Some assortments have declined in price, but for Aber’s production profile, these declines have been more than compensated by significant increases in other assortments that make up the greater part of our revenue stream,” states Aber in its annual report.

Good timing

Rio Tinto’s socio-economic monitoring report for the Diavik operations states: “Timing of rough Diavik diamonds in the marketplace has been excellent and attracted a high level of interest, with prices achieved being higher than feasibility-study projections . . . . Most of the value of the production lies in white stones of one carat and larger, of good commercial clarity and shape. The breadth of Diavik’s product profile means that most of the world’s established diamond polishing centres are interested in receiving a share of Diavik diamonds.”

Rio Tinto has embarked on a 2-year, US$265-million optimization program at Diavik. The mine’s strong performance and improved plant throughput mean, in effect, that the A-154 pit will be mined-out sooner than expected. The Diavik partners have approved a revised mine plan that would accelerate production. “Rio Tinto wants to translate this orebody into cash in a good diamond market, and we share that view,” says Gannicott.

The revised mine plan calls for the A-418 pit to come on-stream more quickly than first planned. The construction and development of the A-418 dyke are expected to cost US$190 million and take two years to complete. Production from the A-418 pit is scheduled to begin in early 2008. To construct the 1,300-metre-long dyke, more than 1 million tonnes of crushed rock fill are required. The A-418 dyke will join the existing A-154 dyke to the north and East Island to the south, allowing safe open-pit access to the A-418 kimberlite.

In addition, Rio Tinto has launched a feasibility study to determine the best underground approach for mining the A-154 South, A-154 North and A-418 pipes. Major considerations in mine design are the inherent weakness of the kimberlite and water inflow. A production-size exploration decline is being driven to provide access to the three bodies in order to test underground stoping methods and assess ground and water conditions. The feasibility studies are to be completed by mid-2007, with the underground mining of parts of A-154 South, A-154 North and A-418 slated to start in 2008.

The cost of the underground program, together with further optimization of the process plant, is expected to be US$75 million. Diavik will continue to pursue opportunities to increase throughput as mining proceeds in the A-154 pit. The mine plan calls for an expanded throughput of 2.5 million tonnes per year to be achieved by 2008. Rough diamond production in 2005 is expected to be between 8.5 and 9.5 million carats. Going forward, Rio Tinto expects Diavik to produce in the range of 8-10 million carats per year through to 2010.

Increased reserves

It has been a little over two years since startup, and the Diavik mine has so far produced 13.1 million carats of diamonds to the end of the first quarter 2005. A higher valuation of the diamonds from A-154 North has resulted in a substantial increase in new underground reserves. A large, 19,342-tonne production-scale bulk sample was mined in 2003 from the top of A-154 North, and the quality of the diamonds proved to be a lot better than originally assumed. A recovered parcel of 11,771 carats was valued at a price of US$82 per carat, versus the original price estimate of US$33 per carat, which was based on a limited parcel of only 157 carats recovered during prefeasibility-stage, large-diameter drilling.

Diavik’s reserves were updated at the beginning of the year to reflect removal of the A-21 pipe and the inclusion of underground re-serves on A-154 North. Proven and probable reserves in the 154 South, A-154 North and A-418 pipes totalled 29.8 million tonnes grading 3.2 carats per tonne, equivalent to 95.6 million recoverable carats. The reserves are equal to about 13 years of remaining life, says Gannicott. The A-21 kimberlite, originally part of the reserves, was instead downgraded to the resource category pending the evaluation of a larger underground bulk sample in about two years from now.

“A-21 is a well-defined body of rock,” says Gannicott. “The reason it doesn’t pass the test for inclusion in the reserves is because of the diamond price. We expect it will come back up into reserve status and provide additional mine life.”

Diamonds from the A-21 pipe were valued at US$28 per carat, based on a limited 90-carat parcel of stones recovered from a small bulk drill sample of just 30.5 tonnes. A larger diamond parcel is needed to confirm the valuation of the A-21 diamonds.

Indicated and inferred resources contain an additional 23.4 million carats in 7.6 million tonnes averaging 3.1 carats per tonne, of which A-21 holds 4.8 million tonnes grading 3 carats per tonne for a total of 14.6 million carats.

The four kimberlite pipes are open to depth. “These kimberlite pipes remain quite robust down at the limits to which they have been drilled so far,” says Gannicott. “There is certainly a lot more potential available below the level of knowledge of the kimberlites.”

64 pipes

He adds that a substantial exploration program is under way, with US$10 million budgeted over the next two years. In total, 64 kimberlites have been found on the Diavik holdings, half of which are diamond-bearing. The Diavik land package covers nearly 2,400 sq. km in the Lac de Gras region. Two new kimberlite pipes were discovered last year: one was 4 km east of the A-154 pit; the other, 55 km northeast of the mine site.

Rio Tinto, through its diamonds group, has a 60% interest in Diavik, a 100% interest in the Argyle mine in Western Australia, and a 78% stake in the small Murawa mine in Zimbabwe, which started production in 2004. Diamond sales offices are in Belgium and India. In 2004, diamonds accounted for 8% of the Rio Tinto’s group operating assets while contributing 5% to annual sales volume. The diamonds group contributed US$169 million to Rio’s 2004 adjusted earnings (50% more than in 2003), assisted by the operating success of the Diavik mine.

The Argyle mine, in Australia’s Kimberley region, accounts for about a fifth

of the world’s diamond production. Leigh Clifford, Rio Tinto’s CEO, described the mine’s 2004 performance as a “low-grade year in a tight mine.” Argyle brought in US$23 million in net earnings in 2004, down a substantial 68% from 2003. Carat production, year over year, was off 33%. In 2004, Argyle produced 20.6 million carats from the treatment of 9.6 million tonnes of lamproite ore grading 2.15 carats per tonne.

Tight mining conditions, as a result of the deepening open pit, limited mine production during the first three-quarters of the year. This was exacerbated by the relatively high turnover of staff and the inability to recruit replacements in time. A combination of uncertainty about Argyle’s mine life, the possibility that the mine would close at the end of the life of the open pit, and a buoyant labour market meant that experienced operators and tradesmen started to leave in higher numbers.

There were also concerns about ore grade. Production was primarily in the northern part of the pit, which has a lower grade. Argyle was also processing from stockpiles, which have a relatively high clay content, and this led to less-than-optimal processing throughput. In late 2004, Argyle saw improvements in maintenance and fleet availability, with production returning to normal.

For the first three months of 2005, Argyle churned out a much improved 8.6 million carats as a result of processing 2.3 million tonnes of ore grading 3.69 carats per tonne.

Winding down

Proven and probable reserves at the end of 2004 totalled 36.5 million tonnes grading 2.9 carats per tonne, equivalent to 104 million carats. Open-pit production at Argyle is expected to wind down by 2008. Ashton is in the midst of feasibility studies of a proposed underground operation, which could extend the mine’s life to 2020. The feasibility work entails driving a 2.5-km-long exploratory decline to obtain geotechnical information. A production decision is expected sometime in the second half of 2005.

“If we progress, and there is still some critical uncertainties, this would be an investment of around half a billion dollars,” says Clifford.

Undeveloped resources total 160 million tonnes grading 2.7 carats per tonne, equal to 432 million carats.

“The Argyle production is cheap, about twelve dollars (U.S.) per carat, and it may well not support underground mining, even in today’s diamond market,” says Gannicott. “The market for the kind of typical Argyle goods is not performing as well as other parts of the diamond market.”

The Argyle production is predominantly one of inexpensive, small, coloured goods. A large proportion consists of small brown-to-yellow coloured stones, as well as some near-colourless and colourless diamonds. Of the diamonds extracted from the mine, 5% are gem-quality, 25% are industrial, and the remainder are termed near-gem. More than 90% of the mine’s production ends up in India’s cutting and polishing centres. Since operations began in the mid-1980s, Argyle has mined more than 700 million carats of diamonds. Argyle has developed a niche for its famous “pink diamonds,” which are sold through an annual tender process. The pinks are but a tiny portion of Argyle’s production: a fraction of 1%. The price for pink diamonds regularly exceeds US$100,000 per carat. The 2004 pink tender comprised 60 stones totalling 55.53 carats, versus the 2003 tender of 48 pink diamonds weighing 45.6 carats.

Argyle sold 24 million carats on to the world market in 2004, generating sales of US$320 million, which translates into an average carat price of US$13.

Be the first to comment on "Aber looks to Harry Winston for added value"