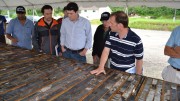

Quest Rare Minerals (QRM-T, QRM-X), which owns the Strange Lake rare earth deposit in northern Quebec, recently held a tour of its mini-pilot plant at Process Research Ortech in Mississauga, Ont., where it’s testing the solvent extraction circuit before scaling up the program this year.

In a Jan. 31 presentation, the firm explained how the mini-program will process a small sample of ore from Strange Lake’s high-grade B zone to confirm the previously defined flow sheets to extract zirconium, niobium and rare earth concentrate.

Quest began bench scale work on the circuit in January 2012 and has since been tweaking the processes. The zirconium solvent extraction for the mini-pilot program kicked off in January 2013, with niobium and rare earth concentrate separation set to begin in the coming months.

Quest’s vice-president of operations Colin Lindsay says the purpose of the mini-program is to “iron out the wrinkles” before trucking down and consuming larger quantities of sample.

The current program will mainly test if the organic reagents used in the circuit could be recycled without degeneration or metal buildup, Lindsay says, explaining organic reagents are oil-based and particularly selective at picking out the metals of interest in an aqueous solution.

“So what you are doing effectively is mixing oil and water… You mix it up in an emulsion and it looks a bit like salad dressing. The value metals will transfer over to the organic phase and the aqueous phase is diluted. Then you have to strip the metals out of the organic, which goes back to the aqueous solution,” he says.

But the first step is getting the material from the mine in the solution before separating the metals, says Mike Robart, Quest’s process metallurgist, adding the circuit was designed by Colorado-based Hazen Research.

The initial steps include grinding the crushed ore prior to mixing it with sulphuric acid. Once mixed, the brownish-grey material is heated in a roasting kiln, where the acid breaks down the material to produce sulphates containing the value metals, which are readily soluble in water. The excess acid is subsequently recovered and recycled.

The dry calcine, a grayish-white in colour, is leached and then filtrated and washed to form a pregnant leach solution containing the desired metals, with zirconium being the first in line to be recovered. Once the zirconium solvent is isolated it is neutralized to produce zirconium oxide product.

During the site visit, Quest demonstrated how zirconium oxide is produced via the aforementioned steps, without specifying the neutralizing reagent. Once the zirconium solvent circuit has been operating for some time, Robart says the downstream steps of extracting niobium solvent and rare earth oxalate will be included, noting both have been defined at bench scale with over 90% recoveries.

Niobium solvent is extracted after adjusting the PH levels of the remaining solution and then converted into niobium oxide. Following that uranium and thorium are removed and disposed, and oxalic acid is added to the leach solution to precipitate the rare earth metals and yttrium while leaving contaminants such as iron and magnesium behind in the solution, Robart notes. “So that concentrate is what we filter out and that has been defined here today at bench scale and moving forward will be confirmed at the pilot scale,” he adds.

Quest says bench scale work to separate the individual rare earth elements is ongoing, but will not be part of the mini-pilot program, which is costing the company roughly $250,000 a month.

The results from the current program will be incorporated in Strange Lake’s feasibility study and not in the upcoming prefeasibility study (PFS) expected within six months.

On Feb. 11 Quest updated the market on the PFS cautioning start-up and operating costs are anticipated to have ballooned since the September 2010 preliminary economic assessment. The economic study envisioned building a 4,000-tonne-per-day open-pit mine at the project’s B zone for $563 million, with total operating costs coming in at $102 per tonne milled.

Quest closed the day down nearly 5% at 92¢ in Toronto.

Be the first to comment on "Quest fires up mini-pilot plant for Strange Lake"