On the morning of May 18, 2020, an earthquake measuring 4.1 on the Richter scale rocked northern Sweden, inflicting serious damage to the century old LKAB iron mine in the town Kiruna, forcing the company to suspend operations. Five days later, production had resumed, albeit at 30% capacity.

That swift recovery was due, in no small part, to 30 surveys conducted at depths of 1,200 metres by a drone-mounted device called Hovermap – a remarkable piece of portable, versatile technology developed in Brisbane, Australia-based Emesent Pty Ltd.Embedded in Hovermap, which weighs a mere 1.8 kg, is software that allows simultaneous autonomous flight and a light detection and ranging (LiDAR) based 3D scans that provide mine operators with highly detailed images of underground environments.

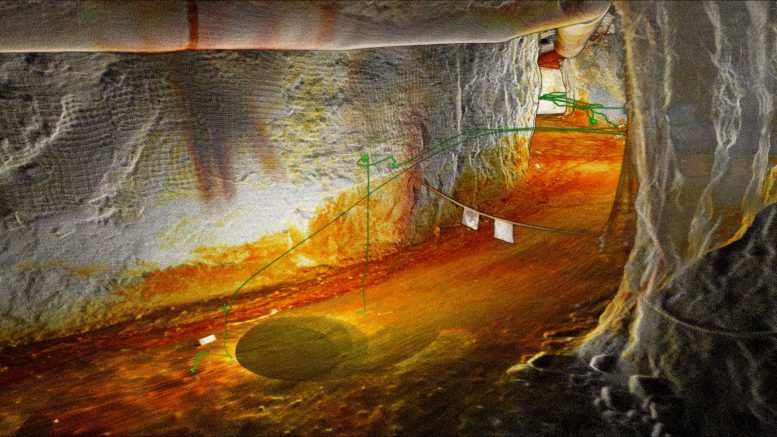

In the case of the LKAB iron mine, operators received detailed images of rock falls, damaged ventilation tubes and collapsed mesh, among other things, scattered over more than a kilometer of underground workings. Hovermap is equally effective in assisting mine planners and operators with daily operations. Indeed, the technology has proved so effective that it is now being used worldwide by 80 different companies and Emesent was only launched in November 2018.

Emesent co-founders Dr. Stefan Hrabar, who serves as chief executive officer, and chief technology officer Dr. Farid Kendoul, spent 10 years as scientists at Australia’s Commonwealth Scientific and Industrial Research Organization (CSIRO) developing and perfecting the software that powers Hovermap.

“We spent a lot of time optimizing the software systems so they can do mapping and autonomy simultaneously and in real time,” says Hrabar. “That’s why Hovermap is so special.”

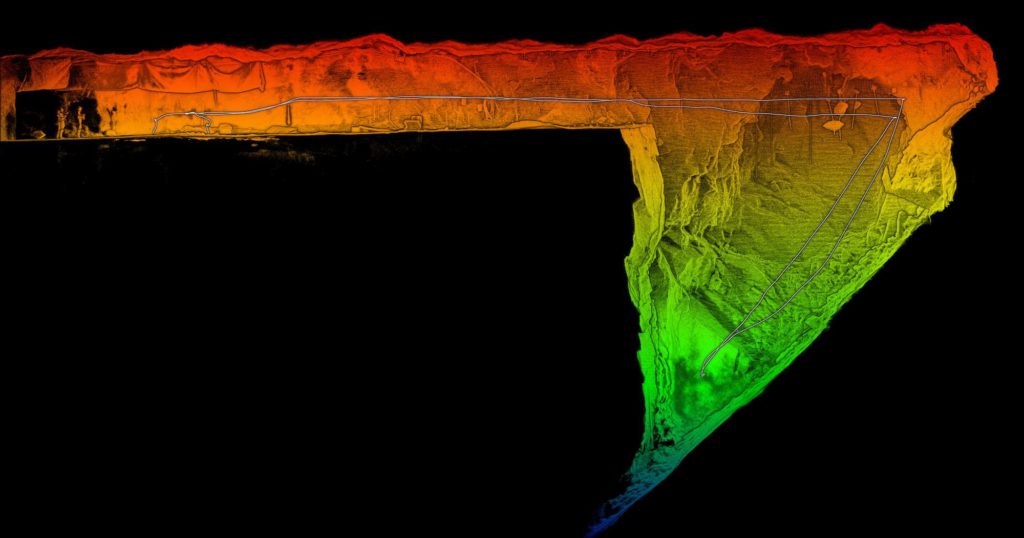

Hovermap is commonly used to provide mine operators with detailed 3D maps of stopes after blasting. An operator working underground with a tablet can launch a drone with Hovermap mounted to the undercarriage. The drone flies autonomously, guided only by waypoints established by the operator before the flight began.

While the drone is in motion, LiDAR scanner constantly emits pulses of infra-red light that bounce off hard surfaces and come back to the device as data points that construct a 3D image.

“As soon as it is switched on and scanning, Hovermap streams a real-time map to a tablet,” says Hrabar. “If it is flying into a stope you can see the size and shape of the stope. You can make sure a blast has gone according to plan.”

For several years now, mining companies have been relying on LiDAR and laser scanners to survey stopes, but they were much less effective and efficient than a drone-mounted scanner. “Usually, you’d put the scanner on a tripod or at the end of a long pole,” says Hrabar. “You’d have to do scans from three or four locations. We’ve seen situations where it would take three hours to scan a stope. Now with a single flight of 10 minutes, you can capture a whole stope with better detail.”

Hovermap can be used for much more than mapping stopes. It can survey inaccessible vertical environments such as ventilation shafts and ore passes. The device can be mounted on mobile equipment to scan muck piles at the bottom of a stope to assess the size of the ore fragments that will be shipped to crushers. With the device in hand, workers walking underground can capture scans of tunnels and drifts looking for potential safety hazards.

The real-time data captured by Hovermap can be transferred from a tablet to a laptop and sent to surface where it is processed to produce much more finely detailed 3D maps. “Geotech engineers use it to map geotechnical structures,” says Hrabar. “Surveyors use the data to calculate volumes of ore extracted from a stope.”

Apart from being portable and versatile, Hovermap is relatively easy to use. “We can train surveyors or geotechs within two days and they’re operating the drone underground,” says Hrabar.

Most mining companies – especially larger ones – prefer to own and operate their own drones and Hovermap units, but some rely on independent service providers to conduct scans on an as-needed basis.

The world of mining is forever evolving, and mining companies are becoming ever more reliant on devices like Hovermap for several reasons. “They are always under pressure to operate more efficiently and to increase productivity,” Hrabar says. “At the same time, mines are getting deeper because the ore bodies closer to surface have been mined out. That makes them more challenging.”

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by Emesent and produced in co-operation with The Northern Miner. Visit www.Emesent.com – Autonomy technology for industrial drones for more information.

Be the first to comment on "JV article: Emesent’s Hovermap valuable tool after earthquake at Swedish iron ore mine"