Australia’s Danakali (ASX: DNK; LSE:DNK) says filtered seawater is a reliable, unlimited and economic option to use in the sulphate of potash (SoP) production process at its Colluli project in Eritrea.

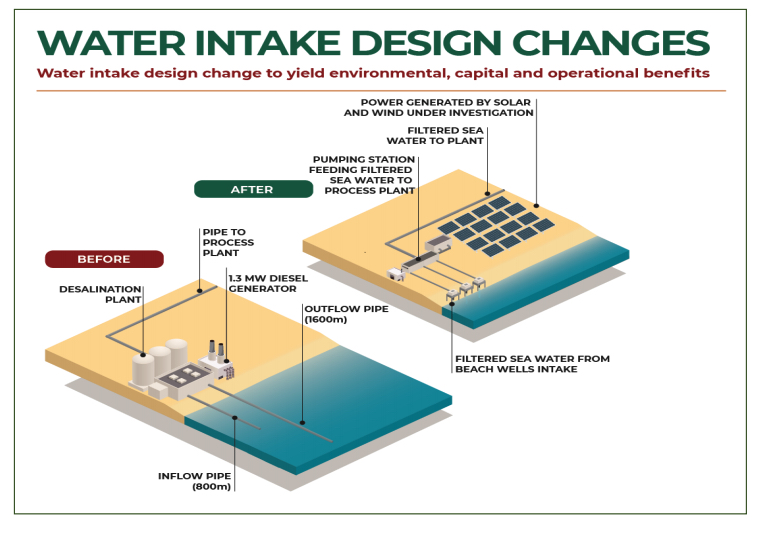

The Perth-based miner said it will now rely on a combination of beach well intake, smaller pumping station and greater renewable energy to pump filtered seawater to the processing plant at the Colluli.

Previously, Danakali would have needed to build a large seawater desalination plant and a pipeline to transport water to the plant.

The water intake treatment area’s (Wita) redesign has a materially smaller onshore and offshore footprint. It also requires less power, thereby reducing operational expenditure (opex), fuel costs and carbon dioxide emissions, Danakali said.

The company noted the new plan requires less capital expenditure (capex) and reduces sustaining capex over the life-of-mine (LoM).

“Using filtered seawater as an unlimited input in our production process is not only a world first, but also a long-term game changer,” executive chairperson Seamus Cornelius said in the statement.

Testing in 2015 proved that SOP could be made from Colluli ore, but only at higher water rates with Reverse Osmosis fresh water.

What was achieved with recent test work with Saskatchewan Research Council in 2021 demonstrates that high-quality product only using seawater is assured, Danakali said.

The innovation adds to the miner’s recent assessment of the use of both solar and wind energy at Colluli.

Since the project is located in one of the world’s most geothermally-endowed rifts, the Danakil depression in the East African Rift Valley, the company said it’s also studying the use of geothermal energy with a view to becoming a zero carbon producer of SoP.

Be the first to comment on "Danakali to use filtered sea water at Colluli potash mine"