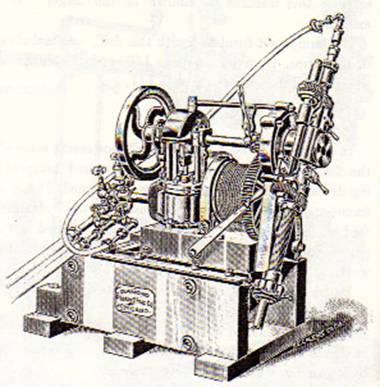

Have you ever seen one of these? Shame on you: you’ve been around too long!

This is an old Sullivan drill built around the end of the 19th century. Some were probably still in use into the 1940s as steam drills. The more modern versions, complete with gasoline and diesel engines were still a hot item well into the 1970s, when I was lucky enough to work on similar beauties.

There was no steam boiler to chop wood for and feed then, but you didn’t see a lot of tractors running around either. If you needed something, you had to go and get it – on your back. That included the rods from the last hole and a 10-gallon drum of gas on your back every day when you walked to the drill. As much fun as it was to have a tractor on the job, it didn’t take a whole lot of work out of the operation.

I recall that the first rod sloops used to come in a bag as a kit. The kit consisted of a Swede saw, four short pieces of EX rod, a chunk of cable and an auger bit. Assembly directions included cutting down some trees, drilling holes through them, inserting the EX rods to hold the cross bunks onto the skids and tie the cable around the front to use as a hitch. A few trips with that contraption and you got to do it all over again.

A drill helper’s day was non-stop: chopping trees into firewood, pulling rods, keeping the waterline running, emptying the odd core tube, making core blocks, carrying stuff, and then eating and sleeping.

The driller didn’t get much of a holiday either. Surface set bits didn’t usually last too long. The old manual chuck, with the big square bolts was fine while everything was new, but a worn bit, old jaws and a set of chuck bolts with worn threads all added up to continual bending over and pulling your back out trying to get the chuck to hold.

The old screw feed didn’t allow the driller to use the drill to break the rods with the head, either. Snapping some of those joints loose with a pipe wrench was no fun.

Wireline

The introduction of wireline drilling had a huge impact on crew durability and production, but in some ways it seemed like you were just moving faster from one laborious task to another. For one thing, the rods were harder to break, even though they didn’t have to be pulled so often.

I recall buying a ¾” ratchet wrench with a special socket one time on my days off and feeling thoroughly modern holding it in my hand in camp on my first day back to work. I was thinking how easy it was going to be to drill with this terrific tool! What a surprise to see a brand new hydraulic chuck sitting on top of the head!

That invention probably saved a thousand bad backs and added a third to drill production. Heaven be saved — the modern age had arrived.

Following this grand event were diesel fuel- and propane-fired water heaters, drill sloops with steel skids, really big tractors, radios — all sorts of labor saving stuff.

In the early 1970s we used to get a special bonus for drilling over 2,500 feet in a month. By the time the 1990s rolled around you were out on your ear if you didn’t do twice that. Impregnated bits and polymer mud systems added tons to that column.

Since that time, there seem to have been a lot of “improvements.” We are constantly being offered new improved widgets that fit into the old gizmos and find they really only affect the price, and not so much the performance.

In spite of all these advances, it seems that it is harder than ever to get new people to stay in our industry. Some manufacturers and some drill people would have you believe that the answer lies in finding the perfect machine, one that practically drills by itself. Who wouldn’t want to work on that drill?

Computer screens now cast light inside drill shacks late at night where gas lamps used to sputter and fizzle. Drill bits seem to last forever; likewise rods. Nobody has to carry anything more than a few feet anymore. Wages have skyrocketed. We used to earn seventy cents an hour, for crying out loud.

And still, the driller and his helper are there, twelve hours a day, seven days a week. And that’s just at the drill. How common is it for the crew to have to drive an hour or more each way to get to the drill? That’s a long day.

Not all, but a lot of drill camps and caring camp cooks have been replaced by a cheap motel and a micro-waved TV dinner. Put that at the end of a 14-hour day with an icy wind blowing up your backside and then talk about technology.

It’s true that work rotations used to be a lot longer than they are now, but, in a lot of cases, the crew can’t take more than a few weeks of that kind of treatment. Would you prefer those new silverbits and jinglebobs over an extra hour’s sleep? I doubt there’s much compromise there.

While there are reasons why we stay in these hotels and make these long commutes, there is no reason to believe they are either enjoyed by the people suffering through them or that they enhance your production in any way. No fancy equipment for the drill site exists that can compensate for a lack of good sleep and proper nutrition.

Drill rods come into the shack one at a time, and at four in the morning, it doesn’t matter much if they’re hung on a hydraulic arm or cradled in your own aching arms, believe me.

And yet, we keep searching for a tool like that as if it were the Holy Grail. In reality, any driller with a little ingenuity and a pair of vise-grip pliers can make a suitable slide out of the first two stands out of the hole that can be used to slide the rest of the rods into/onto the rod sloop with a minimum of physical effort.

Don’t misunderstand the author. We are where we are largely because of advances and technological breakthroughs, and any new improvements are definitely welcome.

However — you knew that was coming, didn’t you? — you have to stop and ask yourself (at least you should), how can we make our industry better? How can we get new and good people interested in becoming tomorrow’s diamond drillers?

Is the answer really in new equipment, or wouldn’t a little more training and human interest go a ways with your people?

For sure, I, believe there has to be more advance in drillers’ living and working conditions.

Somehow, in spite of the growth in the Human Resources industry, drillers seem to be worse off than they were twenty years ago. Higher costs for drills have put more pressure on crews for higher and more-efficient production.

Dilution of available talent has had the reverse effect. Costs have risen even higher to compensate for this factor. Disillusion has set in with some exploration companies. Expectations fall while costs rise. Does that make sense?

Isolated projects aside; has efficiency really increased in the last 10 years? Haven’t drilling costs gone up? Where is the correlation? It is time to review some of the systems we use and try to judge, very objectively, just how much of a difference some of the more costly “improvements” we use, have made.

Do those fancy little goodies that cost four times the old style really give you that competitive edge you’re looking for? I doubt it.

I know what does have an impact – training. MSHA and Common Core training do not produce drillers. Crews have to know how bits cut, what all the parts in a core barrel do, why they should make the drill floor level, how to keep warm/cool. They need training in mud systems, how to calculate hole volumes, some real basic geology.

We need to do some of this stuff before we invest in fancy rod holders and TV screens. No matter how much government required pre-employment training costs, don’t ever think this constitutes an investment in your workforce. This training was legislated precisely because no real training was being done by the industry as a whole back then. What’s changed?

Contrary to the picture I have been painting – I paid a call on a drill crew the other day in central Nevada. They were drilling with a Hydra Winkie. That is definitely not a new or technologically advanced drill rig. And yet, somehow, everybody was smiling, the hole was going down, problems were being solved, everybody knew everybody else’s first name; no “partners” here. Everybody acted as if they knew what they were doing. And they did.

Suffer through two inches a shift less in favor of improving the lot of your drillers. They’ll turn it around and produce double. Don’t leave your HR needs up to your HR department nor for the government to solve. This is just like real life; go see the doctor and he’ll give you a pill, ask your manufacturer what you need and you get a new drill. Ask your people what they need. (…and then go and buy that new drill, already. Don’t be so cheap.)

There is plenty of thoroughly modern, practical equipment on the market that will help both you and your employees meet their goals. Good digging.

— Based in Nevada, the author is a professional driller.

Be the first to comment on "Commentary: Are drillers better off today? (November 14, 2008)"