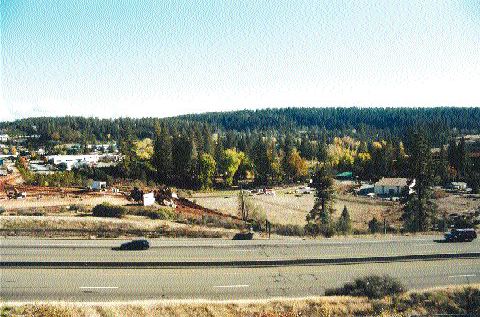

Grass Valley, California — Intent on restarting the past-producing Idaho-Maryland gold mine, just 4 km east of here,

Emgold is looking to commercialize the technology by converting mine tailings from Idaho-Maryland into various ceramic products. The overall impact the process has on the project’s economics will be determined by a feasibility study that is now under way.

Under an agreement, Emgold has paid privately held Ceramext US$100,000 and issued 200,000 shares. Ceramext is controlled by Ross Guenther, a director of Emgold. The deal also gives Emgold the exclusive licence for the Ceramext technology for conversion of mine tailings and other waste materials into ceramic products worldwide.

Ceramext has tested tailings from the Idaho-Maryland mine and produced high-quality ceramic blanks that can be formed into a variety of products using standard and proprietary finishing technologies.

The new ceramic-forming technology, developed by Guenther, uses vacuum hot extrusion to produce ceramic products. Mine tailings are heated in a vacuum extruder until enough liquid is formed to develop the plasticity required to extrude the material. The pore-free material is then forced through a die at temperatures of between 1,100 and 1,200 Fahrenheit. Additional forming steps mould the material into its final shape.

Owing to the superior physical properties (such as modulus of rupture values in excess of 10,000 p.s.i. and extremely low water absorption values), products manufactured using the extrusion process exhibit high strength and superior freeze-thaw characteristics, compared wth standard ceramics. The extrusion process is best-suited to products such as ceramic floor and wall tile, roof tiles, brick, and even tableware and cookware.

Conventional forming processes require many additional steps, such as wet extrusion and pressing or spray drying and dry pressing, and are therefore more capital-intensive. Drying and firing are not required in the Ceramext process.

The process has been demonstrated in laboratory trials on a variety of materials, including coal, lignite, biomass fly ash, bottom ash, slag, clays, volcanic ash, as well as mine tailings. In the U.S. alone, more than 100 million tons of coal, lignite and biomass fly ash are produced every year, and very little of this material can be used as additions to cement products. Most of it finds its way to landfills.

Golden Bear Ceramics, the wholly owned subsidiary of Emgold, is designing and building a pilot and demonstration plant in Grass Valley to commercialize the ceramic technology.

This plant will be used to produce various ceramic products, including bricks and tiles, which will be subjected to product and marketing studies. Emgold intends to conduct a feasibility study to determine if a full-scale plant can consume all of the tailings from the Idaho-Maryland mine (provided the mine feasibility study indicates that the historic mine can be profitably put back into production).

Toward that end, Emgold has kicked off a 15,000-to-17,000-ft. program of surface drilling at the mine-site. In December 2003, the Grass Valley Planning Commission unanimously approved a 6-month extension to the permit that allows Emgold to conduct surface exploration. Boart Longyear has been awarded the diamond drilling contract.

“We’ve adopted a three-prong approach,” said Emgold President William Witte. “The first is to finish the surface drilling. The thing is to start the permitting process. We have a lot of the background information completed, so it’s mostly a matter of hiring the independent consultants and submitting the first part of the application for the mine-use permit. That permit will allow us to put a decline in and perform underground exploration so that we can complete the feasibility study and make a production decision. The third thing is to get the ceramics pilot plant up and running so that we can start producing sample products and do a feasibility study.”

High-grade zone

This second-phase program is designed to test a high-grade gold zone, discovered late last year, as well as other high-grade targets in the westernmost portion of the Idaho Deformation Corridor.

These targets are in addition to the known resources at the Idaho-Maryland mine. In April 2003, Emgold tabled a revised measured and indicated mineral resource of 1.7 million tons averaging 0.28 oz. gold per ton, or 472,000 contained ounces gold. The inferred portion of this resource is 2.5 million tons grading 0.38 oz. gold per ton, or 934,000 oz. gold. The resource calculations used a cutoff grade of 0.1 oz. gold per ton. The calculations are in accordance with National Instrument 43-101 standards.

The largest blocks of indicated and inferred resources were developed at the 2,000-ft. level in the Idaho 23 vein and at the 2,400-ft. level in the Idaho 1 vein. Emgold a large quantity of indicated and inferred resources are also in the Idaho 52 vein, from the 2,700 to the 2,800 levels, and the 80 Vein, from the 1,700 to the 2,070 levels.

This year’s program will test the entire width of the Idaho Deformation Corridor along a 1,500-ft. strike length. Emgold will focus on high-grade lode targets, including: the Idaho “120 vein” target, the Idaho “1 vein,” the Idaho “192 vein,” and a complex set of high-grade link veins in the corridor.

Research of the historic Idaho-Maryland database has revealed that there is a coincidence of localized, pipe-like, carbonate-sericite alteration blooms in most areas of significant underground gold production. An alteration bloom in the 120 vein target area remains almost entirely unexplored. Last year, hole IDH-1 targeted this alteration bloom and cut the Idaho 120 vein. Assays returned 10.1 ft. averaging 0.93 oz. gold per ton starting at a down-hole depth of 528.2 ft. The alteration bloom measures 500 ft. along strike and 150 ft. in width.

Dewatering

Emgold has applied for a mine-use permit, which will, in part, entail dewatering of the Idaho-Maryland mine workings and construction of a decline. The company hopes to test underground targets not readily accessible from the surface. The application will also include provisions for Emgold to operate a staged mining operation of up to 2,400 tons per day if a positive feasibility study is completed and production decision is made.

Said Witte: “Historically, since 1960 there have been thirty-seven gold mines that have applied for mining permits [in California], and all of them received the permit between fifteen and twenty-four months after submitting the application. There is a perception outside of California that you cannot get a mining permit, but nothing could be further from the truth. The state is still one of the biggest mining jurisdictions in the world.”

In December, Emgold closed a brokered private placement of 10 million units priced at 75 each, for gross proceeds of $7.5 million. A unit consists of one share and half a non-transferable share purchase warrant. Each whole share purchase warrant entitles the owner to buy one additional share of Emgold for two years from closing of the private placement, at an exercise price of $1 per share. An additional $846,000 was raised through the exercise of previous warrants. Emgold has 46.9 million shares outstanding and 57.3 million shares on a fully diluted basis.

Except for a concrete silo and some old foundations, little is left of the huge Idaho-Maryland mining complex. The mine, discovered in 1851, produced from 1862 to 1956 and is the second-largest underground historical producer in California after the adjacent Empire mine, which cranked out more than 6 million oz. before closing in 1957. In total, the Idaho-Maryland mine produced 2.4 million oz. gold from 5.5 million tons of ore for a recovered grade of 0.43 oz. per ton. The mine’s closure in 1956 was attributed to soaring wage and material costs amid a fixed gold-price environment (US$35 per oz. at the time).

Mesothermal

The Idaho-Maryland project represents a structurally controlled, mesothermal gold deposit in the northern portion of the Sierra Nevada Foothills gold belt. The mineral rights, about 2,750 acres, are contiguous below 200 ft. from the surface. However, Emgold does hold 37 acres of surface rights around the old New Brunswick shaft, as well as 56 acres of surface rights west of the old Idaho shaft.

According to the revised agreement with the mineral rights-holders, the BET Group, the deal includes a 5-year mining lease (at June 1, 2002) and and option to buy the property for US$4.3 million. This cost will increase by 3% each year to the time of the purchase. During the term of the lease, any production from the property is subject to a 3% net smelter return royalty, plus quarterly payments of US$25,500.

There are several styles of gold mineralization at the Idaho-Maryland mine, including gold-quartz veins, mineralized black slate bodies, mineralized diabase slabs and altered mineralized ultramafic schists.

Emgold’s current deposit model identifies structural features that may host gold-bearing vein sets and explain the varied mineralization styles. The company believes that mineralized vein sets are controlled by four structural features that include: mine-scale boudinage neck features; contact areas of tectonic slabs; local flexures and irregularities in the plane of the Weimar fault zone; and shallowly dipping link faults.

About 80% of the gold produced from the mine came from quartz-dominated veins and the adjacent wallrocks. These veins ranged from 1 to 25 ft. in thickness. The most significant ore shoot was 650 ft. in vertical extent and plunged continuously at a shallow angle for 5,600 ft. Between 1862 and 1894, the shoot produced more than 1 million oz. gold from fewer than 1 million tons of ore.

All the known gold-producing veins are hosted in a triangular block of ground bounded by in-dipping faults on the north and southwest. These form a keel-like zone plunging gently to the southeast. The Keel zone contains 64 known veins, all but two of which have been exploited by mining.

Be the first to comment on "Emgold sees profits in ceramics from tailings"